| Key Takeaway: Sizing a water softener is straightforward when you have three inputs: tested hardness (gpg), typical daily use, and household size. |

Right-sizing prevents two common frustrations: constant regeneration from an undersized unit and wasted salt from an oversized one.

Capacity isn’t just a big number on a spec sheet; it’s the grains of hardness your softener can remove between regenerations at a given salt dose. The goal is reliable soft water with efficient salt use—and enough reserve to handle laundry day, guests, or seasonal swings.

Start with three numbers you’ll actually use

Hardness is measured in grains per gallon (gpg) and represents dissolved calcium and magnesium. Daily use is the gallons your household runs through in a day. A simple planning figure is 60–75 gallons per person, per day; adjust up for large homes, long showers, or lots of small laundry loads.

Disinfectants such as chlorine or chloramine don’t affect capacity, but iron and manganese do. If a test reports iron, many pros “compensate” hardness (for example, add 3–5 gpg per 1 ppm iron) to keep performance steady. A quick water test provides the gpg, any iron/manganese, and the inputs you need to size accurately.

What capacity really means (beyond the model name)

The capacity rating (e.g., 32,000 grains) is the amount of hardness a system can remove between regenerations at a specified salt dose. Higher salt doses yield more capacity but lower salt efficiency; lower doses increase efficiency but reduce capacity per cycle. Modern metered valves let you tune this balance so you regenerate when capacity is truly used—not by a fixed calendar.

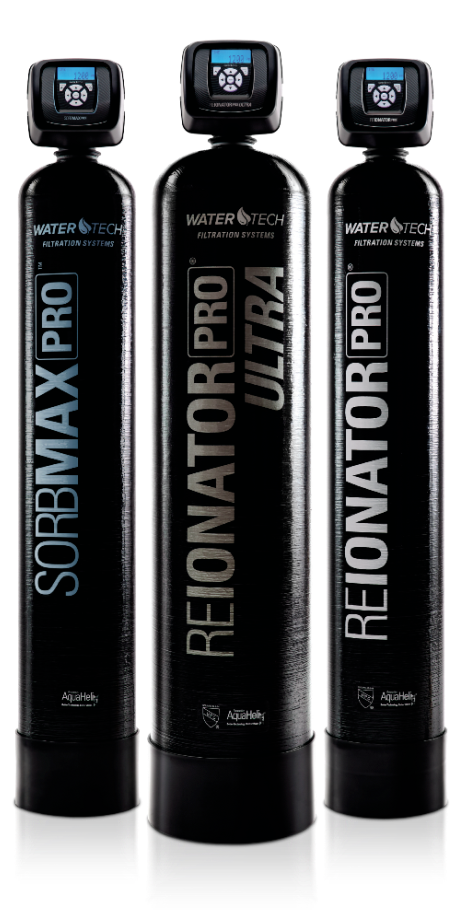

Look for demand-initiated control (metered), an accessible bypass, and programming that lets you set salt dose and reserve. These details are common across the Pro Series so you can match capacity to your household rather than forcing your household to match the unit.

What size do you need? a three-step shortcut

- Calculate daily grains to remove. Multiply tested hardness (gpg) by daily gallons. Example: 10 gpg × 240 gallons/day (family of four at ~60 gpd each) = 2,400 grains/day.

- Choose a regeneration window. Target 7–10 days for efficiency and convenience. Example: 2,400 grains/day × 8 days ≈ 19,200 grains between regenerations.

- Match a working capacity, not just the model name. A unit with ~20,000–24,000 grains of working capacity at an efficient salt dose fits this example and leaves room for peak days.

| Input | Example | Notes |

|---|---|---|

| Hardness (gpg) | 10 | Use a recent test; compensate for iron if present. |

| Daily gallons | 240 | ~60 gpd × 4 people (adjust to your home). |

| Daily grains | 2,400 | Hardness × daily gallons. |

| Days between regens | 8 | Plan for 7–10 days. |

| Working capacity target | ≈19,200–24,000 grains | Choose a model/dose combination in this range. |

Regeneration basics (and why they matter)

Demand-initiated (metered) control regenerates only when needed. This maintains consistent softness and improves salt efficiency. Programming typically includes salt dose, reserve (a buffer so you don’t run out mid-day), and a preferred regeneration time (often overnight). Larger families, very hard water, or frequent guests may justify a little extra capacity to keep the 7–10 day rhythm intact.

Timer-based systems regenerate on a schedule regardless of actual use. They can work in steady-use scenarios, but metered control is usually a better match for real households where use varies week to week.

Avoid the common sizing traps

Undersizing shows up as frequent regeneration and occasional hardness breakthrough on busy days. You’ll also see higher salt and water use from constant cycling. Fixes include increasing resin volume, adjusting salt dose, or stretching the regeneration window if capacity allows.

Oversizing adds cost with little benefit if it pushes regenerations too far apart. Long intervals can allow resin to foul more easily in some waters and may invite inefficient high salt doses “just because.” A balanced setup—enough capacity to ride through peaks, but not so much that you regenerate once in a blue moon—tends to perform best.

Special cases worth planning for

- Iron and manganese: Even small amounts influence sizing and care. Pre-treatment or compensation keeps resin healthy and performance steady.

- Very high hardness: Larger resin beds or staged systems may be appropriate to maintain efficiency at reasonable salt doses.

- Municipal taste/odor: Softening does not address chlorine or chloramine; many homes pair softening with whole-home carbon within the Infinity Series.

- Drinking water at the sink: Point-of-use reverse osmosis is a compact upgrade for beverages and cooking within the city specialty products.

Choose a model that fits the math

Once you know the working capacity you need, pick features that make ownership easy. A metered valve, programmable salt dose, accessible bypass, and safety features (overflow protection, brine safety float) are practical. Families often match these needs inside the Pro Series, selecting resin volume and control settings to hit their target interval and salt use.

Install, verify, and keep it simple

Point-of-entry placement ensures every tap benefits. Plan for plumbing layout, drain routing, and an outlet near the valve. After startup, verify softness with a quick test, then confirm the valve is metering flow and the reserve is set so you don’t run out at peak times. Model-specific references are collected in support.

FAQs

How many grains of capacity do I need?

How often should a softener regenerate?

Does a bigger model always perform better?

What if my hardness changes seasonally?

Bottom line

Sizing a water softener is easier with a recent test and a few household numbers. Calculate daily grains, pick a 7–10 day interval, and choose a working capacity that meets that target at an efficient salt dose. If you’d like a quick double-check on your math or model choice, a dealer can confirm capacity for typical use and set programming to match your home.